In the plastic industry, hollow products are very large, so blow molding and other processing technologies have become a permanent topic. Plastic blow molding is a common method of forming thermoplastic materials. This technology allows the hot melt billets in the mold to expand into hollow products under air pressure, mainly including injection blow molding, extrusion blow molding, tensile blow molding, and blow molding films.

In the plastic industry, the quality of hollow products is very high, so blow molding processing technology has become an eternal topic. Plastic blow molding is a common method of forming thermoplastic materials. This technology allows the hot melt billets in the mold to expand into hollow products under air pressure, mainly including injection blow molding, extrusion blow molding, tensile blow molding, and blow molding films.

As the third plastic processing and molding technology, plastic blow molding is second only to extrusion molding and injection molding, with simple processing technology, low energy consumption, and high production efficiency. In addition, molding technology can be produced on a large scale and products can be diversified. In addition to hollow containers of different shapes and capacities, daily necessities, and children's toys, it can also produce industrial hollow products for different purposes, widely used in industries such as food, chemical, automotive, sports, and home appliances.

The blow molding industry accounts for less than one tenth of the demand in the injection molding market. Blow molded products belong to non-standard customization, which is also a competitive advantage in the industry. In the 1990s, pneumatic devices were manually operated. In the 21st century, hydraulic locking and computer automatic production will be achieved. Now, in recent years, this technology has focused on blow molding Industry 4.0, fully electric drive, and intelligent unmanned production. This industry is not large in scale. The products and blow molding equipment are not standardized, and attention is paid to industry sedimentation. The prospects are good, and the competition is smaller than in the injection molding industry.

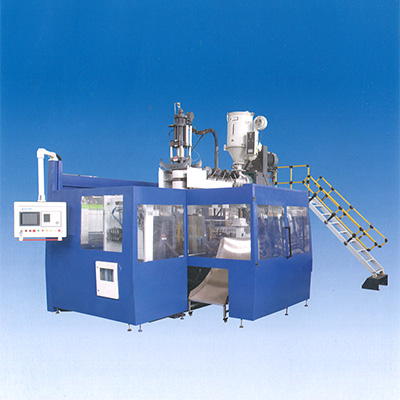

Blow molding machine is a plastic processing machine. After the liquid plastic is sprayed out, the plastic body is blown into a certain shape of the mold cavity by the machine's wind, making the product. This machine is called a blow molding machine. Plastic is melted and quantitatively extruded in a screw extruder, then formed through a mouth film, cooled by a wind ring, pulled by a tractor at a certain speed, and wound into a coil by a winding machine.

Blow molding, also known as hollow blow molding, is a rapidly developing plastic processing method. The tubular plastic parison produced by extrusion or injection molding of thermoplastic resin is placed in the mold when it is hot (or heated to a softened state), and compressed air is immediately introduced into the parison after the mold is closed, causing the plastic parison to be blown and adhered to the inner wall of the mold. After cooling and demolding, various hollow products are obtained. The manufacturing process of blown film is very similar to hollow products in principle, but does not use molds. From the perspective of plastic processing technology classification, the forming process of blown film is usually included in extrusion. During World War II, blow molding technology began to be used to produce low-density polyethylene bottles. In the late 1950s, with the birth of high-density polyethylene and the development of blow molding machines, blow molding technology was widely used. The volume of hollow containers can reach thousands of liters, and some production is already controlled by computers. Plastics suitable for blow molding include polyethylene, polyvinyl chloride, polypropylene, polyester, etc. The obtained hollow containers are widely used as industrial packaging containers.

According to the production method of preforms, blow molding can be divided into extrusion blow molding and injection blow molding. New developments include multi-layer blow molding and stretch blow molding.

浙公网安备33028102001314号